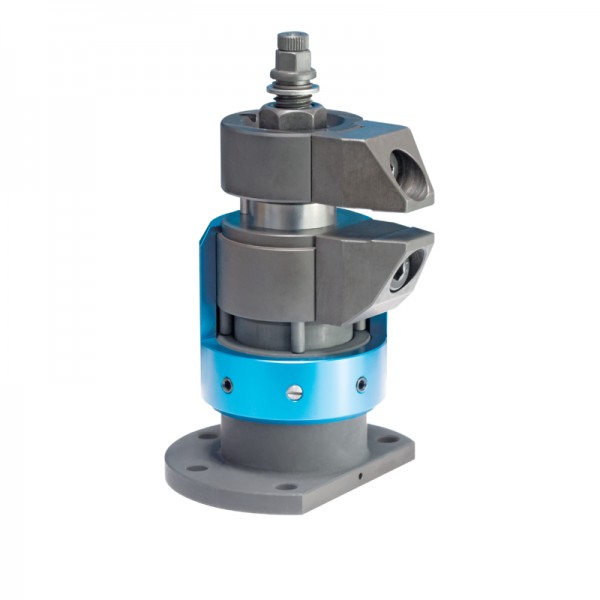

Halder - EH 23320.: Floating Clamps ‒ compact construction, separate clamping and locking M 12

Floating clamps with separate clamp and locking are used to clamp and support additional clamping points on extremly pliable workpieces. Both, clamping and supporting force can individually be designed.

The benefits of the floating clamp are:

- avoids vibration during the processing

- clamps ribs, beads and shackles to reinforce clamped components

- distortion-free clamping of raw parts

- compact version with reduced height.

Material

Adjustable body

- Aluminium, blue anodised

Body

- Case hardened steel, nitrided, manganese phosphate treated and ground

Clamping Jaws

- Case hardened steel, nitrided, manganese phosphate treated

Assembly

- Mount the floating clamp (mounting holes for M 6, see drawing ) onto the device.

- Adjust the height limit stop and the rotating area with the sleeve and clamp with a set screw (4x WS 2.5). When setting the height limit, consider tolerance of workpiece.

Operation

- Push the floating clamp downward.

- Pivot the clamping jaws in.

- Release floating clamp. The bottom jaw contacts the workpiece with a low spring force.

- Tighten the fixture nut (WS 18) having a maximum torque of 15 Nm. The workpiece is clamped; the clamp is still floating.

- Thereafter tighten the hexagon collar nut (WS 10 - max. torque 10 Nm).

- The clamping process is finished.

- Releasing is done in reverse order: release hexagon collar nut (WS 10) - release fixture nut (WS 18) - pivot the clamping jaws out.

- Floating clamp is in end position.

Notes

For specific clamping situations, the standard clamping jaws supplied can be exchanged or replaced (see catalogue drawing: screw ISO 4762 - M8 - 12.9, M max. = 43 Nm).

Accessories

As an accessory, we offer clamping jaws with an increased clamping range, refer to 23320.0050-.0058, as well as pivot jaws, refer to 23320.0148-.0156.

INFO & ACCOUNT

INFO & ACCOUNT